chalcopyrite impact mill

A process mineralogy approach to study the efficiency of milling

2020年12月3日 Examination of Mo, Cu, and Fe grade variations for 10 days in both off and on modes of mill shows that closed-circuit mill does not have an impact on comminution

[خذ المزيد]

Impact of mechanochemical effect on chalcopyrite leaching

2015年3月10日 The media size, filling, slurry density and mill tip speed were kept constant at 10 mm, 40%, 40% and 15 m/s respectively. The energy was varied by grinding at 15,

[خذ المزيد]

Impact of mechanochemical effect on chalcopyrite leaching

2015年3月10日 Besides size reduction, stirred mill has the ability to deliver high energy to particles which facilitate crystal structure distortion. High energy stirred milling

[خذ المزيد]

Enhancing flotation separation of chalcopyrite and magnesium

2021年3月18日 Separation effects of sodium polyacrylate (PAAS) and gum Arabic (GA) on flotation of chalcopyrite and magnesium silicate minerals using potassium butyl

[خذ المزيد]

A Review on Novel Techniques for Chalcopyrite Ore Processing

2012年1月1日 2.2. Chalcopyrite Ore Processing. The first step in the chalcopyrite processing is to liberate the copper minerals and remove waste constituents such as alumina, limestone, pyrite and silica so that

[خذ المزيد]

Impact of Mechanochemical Effect on Chalcopyrite Leaching

2014年10月1日 Similar results were obtained when grinding chalcopyrite [8] in a pin type vertical stirred mill, when, with the same mechanochemical effect (the assessment was

[خذ المزيد]

Gravity separation with wave tables, fine gold recovery

Gravity separation with wave tables, concentrating tables, assay supplies, impact mills, micron mill wave table, gold wave table, micron gold recovery 406.826.9330 customerservice@actionmining Account

[خذ المزيد]

Chalcopyrite Common Minerals

Chalcopyrite is a striking, bright yellow, metallic mineral that occurs in nearly all sulfide deposits. Initially, it may be easy to confuse chalcopyrite, or copper pyrite (CuFeS2),

[خذ المزيد]

「压力荷尔蒙」皮质醇到底是什么? - 知乎

在压力刺激下加速分泌,这就是皮质醇 “压力荷尔蒙” 这个名称的由来。. 人们也因此习惯性地将皮质醇视作是衡量压力的核心指标。. 于危机时调动起人体机能,这使得皮质醇在人体

[خذ المزيد]

Mechanochemistry for Energy Materials: Impact of Highâ

Chalcopyrite CuFeS 2, a semiconductor with applications in chemical sector and energy conversion engineering, was synthetized in a planetary mill from elemental precursors. The synthesis is environmentally friendly, waste-free and inexpen-sive. The synthesized nano-powders were characterized by XRD, SEM, EDX, BET and UV/Vis techniques, tests of ...

[خذ المزيد]

Impact of mechanochemical effect on chalcopyrite leaching

2015年3月10日 The media size, filling, slurry density and mill tip speed were kept constant at 10 mm, 40%, 40% and 15 m/s respectively. The energy was varied by grinding at 15, 30, 45, 60 and 90 min intervals. Chalcopyrite concentrate obtained from a mineral processing plant in Chile was used in this experiment. Fig. 1 shows the X-ray diffraction of concentrate.

[خذ المزيد]

Mechanochemistry for Energy Materials: Impact of

2021年8月17日 Chalcopyrite CuFeS 2, a semiconductor with applications in chemical sector and energy conversion engineering, was synthetized in a planetary mill from elemental precursors. The synthesis is

[خذ المزيد]

The effect of regrind mills on the separation of chalcopyrite from ...

2015年11月1日 After regrinding with the stirred mill, chalcopyrite recovery was improved by additional collector in the cleaner flotation, ... it is difficult to distinguish the exact source of these species. As discussed previously, in the rod mill, the main breakage mechanism is impact, and the carried species can remain on the surface of particles of all ...

[خذ المزيد]

Effect of Grinding Media on Grinding-Flotation Behavior of Chalcopyrite ...

Grinding media have significant influence on the flotation of chalcopyrite and pyrite. This effect is mainly related to the change in the surface properties of chalcopyrite and pyrite. This paper investigates the influence of steel ball and nano-ceramic ball grinding on the floatability of chalcopyrite and pyrite. Flotation results, as well-scanning electron

[خذ المزيد]

Impact of Mechanochemical Effect on Chalcopyrite Leaching

2014年10月1日 High energy stirred milling experiments (up to 300 kWh/t) was carried out on chalcopyrite concentrate. The media size, mill speed and slurry % solids were kept constant in this experiment. The...

[خذ المزيد]

Agglomeration-Flotation of Finely Ground Chalcopyrite and

2020年4月23日 In flotation, the size of mineral particles is one of the most important parameters: when the size becomes fine, collision efficiency of the particles and air bubbles becomes low, causing low flotation recovery. To improve the collision efficiency and flotation kinetics, agglomeration using the emulsified oil of finely ground chalcopyrite (D50 = 3.5

[خذ المزيد]

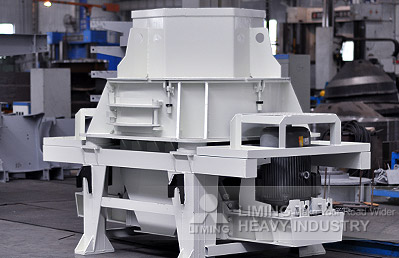

Fine Impact Mills Hosokawa Alpine

The fine impact mills belonging to the Ultraplex® UPZ product line are used for grinding finenesses in the range 50 µm to 5 mm. A wide range of grinding elements is available, making it possible to operate the UPZ as

[خذ المزيد]

Introduction to Mineral Processing - Sepro Labs

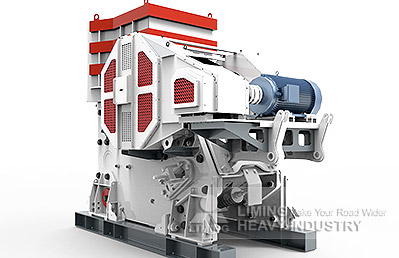

Chalcopyrite does not in and of itself have any direct use as a mineral. ... Impact Crushers Impact crushers involve the use of high speed impact rather than compresssion to crush material. ... Figure 5 – SAG Mill picture and general shape Rod, Ball and Pebble Mills

[خذ المزيد]

Enhancing flotation separation of chalcopyrite and magnesium

2021年3月18日 Separation effects of sodium polyacrylate (PAAS) and gum Arabic (GA) on flotation of chalcopyrite and magnesium silicate minerals using potassium butyl xanthate (PBX) as collector were ...

[خذ المزيد]

A Review on Novel Techniques for Chalcopyrite Ore

2012年1月1日 2.2. Chalcopyrite Ore Processing. The first step in the chalcopyrite processing is to liberate the copper minerals and remove waste constituents such as alumina, limestone, pyrite and silica so that

[خذ المزيد]

RANCANG BANGUN BALL MILL DARI BAJA DIAMETER 20 CM

Kata kunci: prototipe ball mill, screening, grinding, tambang, proses mineral, uranium. ABSTRACT. BUILDING BALL MILL DESIGN FROM 20 CM DIAMETER STEEL FOR CHALCOPYRITE MINERAL DESTRUCTION AS A LEARNING PROCESSING MEDIA OF URANIUM PROCESSING. In the process of initial processing of uranium from the mine

[خذ المزيد]

Effect of mill scale amount on mix leaching of mill...

Download scientific diagram Effect of mill scale amount on mix leaching of mill scale-HCl-chalcopyrite (HCl concentration: 7 M; leaching time: 120 min; leaching temperature: 105 °C ...

[خذ المزيد]

Common Basic Formulas for Mineral Processing Calculations

2016年3月20日 Mill Water to Ore Ratio Requirements. Resistance of Various Materials to Crushing. Pulp Calculations. W—Tons of solids per 24 hours. R—Ratio of weights: solution/solids. ... 79.8% when in the mineral chalcocite, and 34.6% when in the mineral chalcopyrite. A common association is that of chalcopyrite and galena. In

[خذ المزيد]

Mechanochemistry for Energy Materials: Impact of

2021年8月17日 Chalcopyrite CuFeS 2, a semiconductor with applications in chemical sector and energy conversion engineering, was synthetized in a planetary mill from elemental precursors. The synthesis is

[خذ المزيد]

Mechanochemistry for Energy Materials: Impact of Highâ

Chalcopyrite CuFeS 2, a semiconductor with applications in chemical sector and energy conversion engineering, was synthetized in a planetary mill from elemental precursors. The synthesis is environmentally friendly, waste-free and inexpen-sive. The synthesized nano-powders were characterized by XRD, SEM, EDX, BET and UV/Vis techniques, tests of ...

[خذ المزيد]

The effect of regrind mills on the separation of chalcopyrite from ...

2015年11月1日 After regrinding with the stirred mill, chalcopyrite recovery was improved by additional collector in the cleaner flotation, ... it is difficult to distinguish the exact source of these species. As discussed previously, in the rod mill, the main breakage mechanism is impact, and the carried species can remain on the surface of particles of all ...

[خذ المزيد]

Chalcopyrite leaching in novel lixiviants - ScienceDirect

2022年2月1日 Chalcopyrite is the dominant Cu ore mineral in most porphyry deposits, which make up an estimated 70% of the global Cu resource (Singer, 2017), and is also widespread in other important deposit types. As near-surface Cu oxide resources are mined out, chalcopyrite will increase as a fraction of the future global Cu supply.

[خذ المزيد]

Enhancing flotation separation of chalcopyrite and magnesium

2021年3月18日 When the GA dosage exceeds 100 mg/L, the recoveries of chalcopyrite and talc were 77% and 17% respectively, which was the maximum depression effect of talc. Therefore, in the subsequent flotation...

[خذ المزيد]

Impact of Mechanochemical Effect on Chalcopyrite Leaching

2014年10月1日 High energy stirred milling experiments (up to 300 kWh/t) was carried out on chalcopyrite concentrate. The media size, mill speed and slurry % solids were kept constant in this experiment. The...

[خذ المزيد]

$USAU Getting some Premarket volume here.. $5.82 now up 7

The exact metal content will vary over the mine life, but on average, per our prefeasibility study (released December 1, 2021), the concentrate will contain approximately 19% copper, 1.5 oz/ton gold and 1.7 oz/ton silver. The balance of concentrate mass will be made up of chalcopyrite and gangue minerals such as quartz.

[خذ المزيد]

Agglomeration-Flotation of Finely Ground Chalcopyrite and

2020年4月23日 In flotation, the size of mineral particles is one of the most important parameters: when the size becomes fine, collision efficiency of the particles and air bubbles becomes low, causing low flotation recovery. To improve the collision efficiency and flotation kinetics, agglomeration using the emulsified oil of finely ground chalcopyrite (D50 = 3.5

[خذ المزيد]

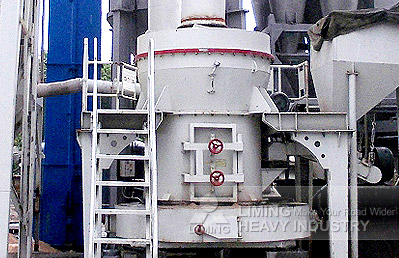

grinding chalcopyrite hydraulic systems - metal ore mill

2013年9月9日 chalcopyrite impact mill - Kefid(USA),INC. ... Chalcopyrite Mill Grinder . for Chalcopyrite is used for grinding Chalcopyrite into powder less than 0 . shmrtei@gmail. what is the environment impact from mining sphalerite . Grinding Solutions. Grinding is the required process when size reduction of below 5-20 mm is

[خذ المزيد]

Effect of Grinding Media on Grinding-Flotation Behavior of Chalcopyrite ...

The chalcopyrite and pyrite are crushed with a small hammer to 1–2 mm, then, the samples were ground in a grinding bowl using the 15 mm nano-ceramic balls and 12 mm steel balls (of the same weight) as grinding media. Firstly, the grinding medium and appropriate amount of sample were added in the grinding bowl.

[خذ المزيد]

Brief history of impact mills

2023年3月28日 Impact mills have been used for centuries to grind materials into fine powders. The first documented use of an impact mill dates back to the 16th century when it was used to grind grains in Europe.

[خذ المزيد]

RANCANG BANGUN BALL MILL DARI BAJA DIAMETER 20 CM

Kata kunci: prototipe ball mill, screening, grinding, tambang, proses mineral, uranium. ABSTRACT. BUILDING BALL MILL DESIGN FROM 20 CM DIAMETER STEEL FOR CHALCOPYRITE MINERAL DESTRUCTION AS A LEARNING PROCESSING MEDIA OF URANIUM PROCESSING. In the process of initial processing of uranium from the mine

[خذ المزيد]

Introduction to Mineral Processing - Sepro Labs

Chalcopyrite does not in and of itself have any direct use as a mineral. ... Impact Crushers Impact crushers involve the use of high speed impact rather than compresssion to crush material. ... Figure 5 – SAG Mill picture and general shape Rod, Ball and Pebble Mills

[خذ المزيد]

A Review on Novel Techniques for Chalcopyrite Ore Processing

2012年1月1日 1.2. Chalcopyrite Ore Production The sulfide ore minerals including chalcopyrite (CuFeS 2), sphalerite (ZnS), galena (PbS) provide the major sources of the world’s base metals (Cu, Zn, Pb, respectively), whereas pyrite is virtually ubiquitous as a metalliferous mineral in sulfide ore deposits (Crang and Vanghan, 1994).The first step in

[خذ المزيد]- چگونه سنگ شکن مخروطی کار

- محطم الكرة بور لو

- تأجير محطم ملموسة في LINCS شمال

- هيكل ناقل مستعمل للبيع

- طاحونة التربة الهند

- لفة طحن في أمريكا

- الأسطوانة مطحنة طحن الخبث

- قطعات یدکی برای سنگ شکن و صفحه نمایش

- الصين آلة المطرقة محطم يستخدم

- نوع جديد غرامة دائمة سحق الفك محطم

- کارخانه سنگ شکن سنگ آهن در جبل پور

- تولید کننده فیلتر فشار ماسه

- طبقة كسارات الفك

- الحجر المتحرك سحق وفقا

- متجر آلة السيارات

- مصغرة كسارة الحجر المورد الهند

- مطحنة الحجر في عنوان الصين

- الحصى حجر سحق سعر الجهاز

- دستگاه خرد کن شن و ماسه سیلیس

- عدد من المطارق في كسارة طن

- مبادئ مطرقة المطاحن

- الفلسبار البوتاس كسارة في ألبرتا

- خطة العمل علىالمحجر

- آلات طحن حجر الذهب للرمل

- شراء كسارات عشب مصر

- نهاية مطحنة مبراة

- محطة كسارة متنقلة بيع في شيلي

- قطع الغيار مطحنة الكرة مقاس

- ريموند مطحنة مسلسل محطم

- هندوستان سازنده ماشین آلات سنگ شکن فکی در چین برای فروش

© Copyright - PETER&X محطم